综合多场景输电线路高清视频监测与智能预警方案

电网规模扩大和输电线路多样化,线路覆盖山区、河谷、城乡结合区及高风险施工区段,存在多种潜在风险:外破行为及施工入侵山火及森林火灾风险山体滑坡、落石、泥石流等地质灾害夜间及恶劣天气下巡检困难动物靠近或异物挂线传统人工巡检效率低、盲区多、发现异···

2025-11-24

双光谱热成像输电线路山火预警视频监测方案

输电线路不断向山区、林区及野生植被茂盛区域延伸,线路运行安全面临的风险不断增加。尤其是山火频发区段,火灾可能造成线路停运、塔杆损坏、导线熔断及电网大面积瘫痪。传统巡检手段在林区、山谷及夜间场景中存在以下问题:巡检周期长,火点发现延迟夜间及烟···

2025-11-24

AI智能分析型输电线路视频监测系统方案

输电线路数量及电网规模的扩大,线路运行环境越来越复杂,尤其是跨山区、跨河谷和城乡结合区段。传统人工巡检方式存在:巡检效率低,周期长难以发现隐蔽风险和微小异常盲区较多,夜间及恶劣天气无法保障监测数据分散,难以统一分析为实现线路全程可视化、智能···

2025-11-24

跨江跨谷输电线路高清视频监测方案

跨江、跨谷输电线路具有跨度大、环境复杂、施工及维护难度高的特点。沿线常穿越高速公路、铁路、河流、峡谷及深山地带,线路运行受外界影响风险高,如:高塔结构受风力影响明显外力破坏易发生在施工区及船舶水域道路及铁路施工可能威胁线路安全江河水位变化带···

2025-11-24

输电线路视频监测系统总体建设方案

随着电网线路跨越场景增多、外力破坏频发、极端天气影响加剧,传统人工巡线已难以满足实时性与精确性需求。视频监测系统能实现 7×24 小时可视化巡查,提升运维效率与线路安全。

2024-09-23

山区输电线路可视化视频监测系统建设方案

我国山地地形广泛,输电线路在山区分布密集,山高坡陡、沟谷深邃,植被茂密且地质结构复杂。山区线路运行环境恶劣,常受滑坡、泥石流、树木倒伏、雷暴大风、野火等自然因素影响,同时存在巡检难、周期长、盲点多等问题。为提升山区输电线路安全运行水平,

2024-09-06

无信号区北斗智能监拍装置在线监测方案

山区、峡谷、无人区等区域基础通信条件的限制,传统依赖蜂窝网络(4G/5G)的监测设备常出现 信号弱、不稳定甚至完全无信号 的情况,导致输电线路巡检、边坡监测、地质灾害预警等场景的安全管理难度持续增加。为了实现 “无信号区域也能实时监测、远程···

2025-11-25

输电线路边坡在线监测方案

输电线路跨越山区、丘陵及复杂地质区域时,沿线常存在大量自然边坡与人工开挖边坡。这些边坡受降雨、风化、地震、植被变化及人为扰动等影响,极易发生崩塌、滑坡、落石等灾害,严重威胁铁塔稳固性和线路运行安全。随着国家对电网安全运行要求不断提高,《电力···

2025-11-25

输电线路北斗杆塔沉降在线监测方案

我国电网规模不断扩大,输电线路杆塔数量庞大且分布广泛,其基础环境复杂多变,包括软土地区、山区、河流冲刷区、冻土带、采空区等。杆塔基础沉降是最常见、也最隐蔽的结构风险之一。当沉降过快或超过设计范围时,可能造成塔身倾斜、基础开裂、导线受力不均,···

2025-11-25

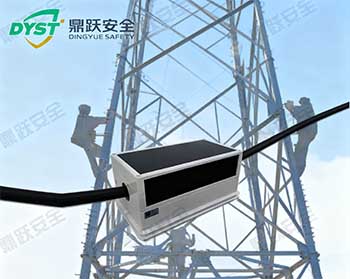

输电线路北斗杆塔倾斜在线监测方案

国家电网和南方电网输电线路规模的持续扩张,杆塔数量不断增多,其分布区域呈现跨山地、跨河谷、多气候带等复杂特征。风荷载、地质变化、基坑扰动、雨水侵蚀、塔基沉降等因素均可能导致杆塔产生倾斜、旋转甚至失稳,给线路安全运行带来潜在风险。传统巡视方式···

2025-11-25

北斗雷达形变可视化在线监测方案

近年来,随着山区高速、铁路、矿山、水利工程的大规模建设,边坡稳定性、安全隐患监控显得尤为关键。传统的人工巡检方式存在滞后性、危险性高、无法持续监测等问题,已无法满足工程级安全要求。北斗雷达形变可视化监测装置依托北斗高精度定位技术与毫米波雷达···

2025-11-24

输电线路北斗风偏弧垂在线监测方案

高压、超高压输电线路不断穿越山区、河谷、风口、跨江等复杂环境,导线在大风、覆冰、高温等自然因素作用下容易产生较大幅度的 风偏、弧垂变化、振动舞动 等问题,严重时会造成相间距离不足、跳闸、线路覆冰断线、异物碰线等风险。传统的人工巡视或定期测量···

2025-11-24

配网行波型故障预警与定位装置方案

配电网智能化水平不断提升,传统依靠录波器、保护装置、人工巡线等方式的故障定位模式,已难以满足“快速、精准、可视化”的现代电网运维要求。配网线路分布广、接线复杂、故障类型多样,尤其在分布式电源大量接入、负荷波动显著的情况下,线路发生瞬时性接地···

2025-11-25

配电故障可视精灵装置方案

配电网规模不断扩大、负荷持续增长以及分布式能源的大量接入,传统的人工巡检与事后排查方式已无法满足快速、精准、智能化运维的要求。故障定位不及时、巡检效率低、停电范围广、抢修时间长等问题日益突出。为提高配电网的运行可靠性与数字化水平,迫切需要一···

2025-11-25

新型一二次融合成套柱上断路器故障测距装置方案

配电自动化建设的不断加速,传统柱上断路器(分界开关)在故障定位、短路隔离、遥信遥测等方面已逐渐难以满足数字化电网的要求。传统设备普遍存在以下问题:测距功能缺失或精度低,故障区段锁定效率不足。二次系统依赖外部电源及复杂接线,可靠性弱。现场巡检···

2025-11-25

架空暂态录波型远传故障定位监测方案

电网规模不断扩大、线路跨区跨境输电比例提升,架空输电线路在复杂地形、覆冰、大风、雷害等因素影响下,故障概率显著增加。传统故障指示器依赖工人巡视排查,不仅耗时长,还容易因地形障碍或天气因素导致排查延迟。特别是在输电线路跨越山区、深谷、河流、林···

2025-11-25

高压电缆故障及隐患监测方案

城市电网结构不断扩张,高压电缆已成为输电系统中最关键的组成部分之一。电缆一旦发生故障,往往会导致大面积停电、重大经济损失,甚至带来安全事故。传统巡检方式主要依赖人工红外测温、抽检式绝缘测试,无法对电缆故障进行实时预警,也难以及时定位问题点。···

2025-11-25

分布式故障定位监测方案

配电网规模不断扩张、线路分支增多、负荷结构复杂度上升,传统依赖人工巡检、单点测控的故障查找方式已无法满足“快速定位、精准隔离、减少停电时间”的现代电网需求。一旦线路发生短路、接地、断线等故障,停电范围大、排查路径长、恢复效率低已经成为制约供···

2025-11-25

电力作业智能手环整体解决方案

电力运维现场长期处于高风险、高强度、高机动性的工作状态,人员作业分散、环境复杂、突发危险多。传统管理方式常依赖人工汇报或离线记录,人身安全保障和健康监测存在明显滞后。近年来,随着可穿戴设备技术成熟,以智能手环为载体的实时监测方案逐渐成为行业···

2025-11-26

北斗高精度智能安全帽解决方案

随着电力施工、石油化工、轨道交通、市政工程等行业安全管理要求不断提升,传统安全帽仅具备基础防护功能,难以承担实时监控、人员定位、行为预警等更高层次的安全管理需求。特别是在复杂、危险及多人员交叉作业环境中,如何实现“人员可视化管理、作业可控化···

2025-11-26

智能头盔解决方案

在电力巡检、建筑施工、矿区作业、铁路巡查等高风险行业中,一线人员长期处于复杂、多变、不可预知的环境。传统安全帽仅具备基础的物理防护功能,无法满足当下数字化、精细化、智能化的现场管理需求。而“智能头盔”作为新一代可穿戴式现场指挥终端,将 高清···

2025-11-26

执法记录仪移动视频监控解决方案

在环境监测、公共交通运营、石油开采、建筑施工、抗洪救灾、电力高压线路抢修等各类高风险、复杂户外作业场景下,传统的固定监控方式已经难以满足移动化、实时化、全覆盖的现场管理需求。作业人员需在不停移动的过程中记录现场环境、工况变化、风险点以及应急···

2025-11-26

布控球智能现场安全管理解决方案

在环境监测、公共交通、石油开采、施工工地、抗洪救灾、电力高压线抢修等作业现场,往往存在环境复杂、作业风险高、指挥协同难度大等特点。传统的固定视频监控难以覆盖临时区域、移动作业点和突发性抢险场景,无法满足快速安装、灵活部署、高清取证和远程调度···

2025-11-26

输电线路航空标志球解决方案

电网建设的迅速发展,跨江、跨河、跨高速、跨山谷、跨铁路等高压输电线路越来越多。这些线路在保障能源输送的同时,也对空中通航安全带来了潜在风险。特别是低空飞行的直升机、农林作业飞机、巡线无人机等,在能见度不佳或复杂地形下更容易与输电线路发生碰撞···

2025-11-26

电力智能安全警示器解决方案

电力施工场景、配网巡检现场以及电力抢修作业的复杂化,传统静态警示牌在夜间或视线不佳环境中的提示能力有限,存在“看不清”“反应慢”“无主动预警”等问题,已无法满足当前电力安全生产的智能化需求。电力智能安全警示器作为新一代主动式现场安全防护设备···

2025-11-26

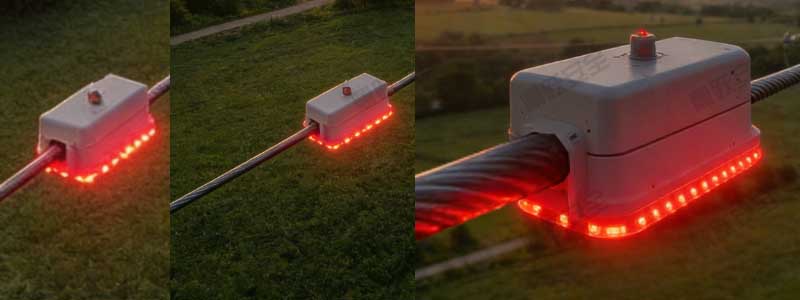

高压线防外破警示灯整体解决方案

我国电网规模不断扩大,高压架空输电线路跨越城市道路、山区农田、施工区域的数量逐年增加。由于外部施工、机械作业、运输车辆超高、无人机误闯、山火等因素持续增多,高压线路外破事件依旧高发,对电网安全运行、人身安全和社会稳定构成巨大威胁。传统的防外···

2025-11-26

太阳能航空障碍灯解决方案

城市建设高速发展以及电力、通信、交通等基础设施的不断加固,高层建筑、铁塔设施、超高烟囱、山地风电场及桥梁等高耸结构物数量持续增加。为了确保航空飞行安全,民航法规要求所有高于障碍限高的建筑及设施须安装航空障碍灯,用以在夜间或能见度较低条件下提···

2025-11-26

高压取电防外破警示装置解决方案

近年来,随着城乡基建工程量的不断扩大,吊车、挖机、运输车辆等大型机械频繁涉入电力通道区域,导致高压线路外破事故呈上升趋势。外力破坏已成为威胁电网安全的主要隐患之一,其中吊车臂杆误碰导线、塔吊提升作业误入电力保护区等情况屡见不鲜。传统的警示方···

2025-11-26

吊车近电预警装置在电力应急的方案

在高压输电线路、变电站及其他带电作业区域,吊车等大型施工机械在作业过程中存在误入安全防护距离的风险,可能引发电弧闪络、触电事故或设备损坏。为保障作业人员和设备安全,同时提高电力应急响应能力,采用近电预警装置对吊车进行实时监测与预警显得尤为重···

2025-05-05

多模融合终端(PDT)的应用方案

多模融合终端(PDT)是一种集多种通信模式于一体的高端通信设备,广泛应用于应急救援、安防、公共安全、物流运输等领域。

2024-12-30

高带宽智能自组网单兵的应用方案

高带宽智能自组网单兵系统是集无线通信、自组网技术与智能设备于一体的移动通信平台。该系统主要为应急救援、军事作战、执法行动等场景提供实时高效的通信与信息共享能力。

2024-12-21

应急自组网解决方案:构建灵活可靠的应急通信网络

应急自组网广泛应用于自然灾害救援、公共安全事件和临时活动保障等场景,为救援行动提供强大的通信支持。

2024-09-02

三防台风预警方案

害的发生的随机性,在较短的时间内能造成较大损失的特沿海台风是海洋重要灾害之一,具有突发性,灾点,每年都有一定数量的发生,造成沿海的重大资源损失和居民生命财产安全隐患。一旦有台风警示:预警预防、宣传、监控、监测、管理是否及时,重要原因都取决于···

2023-09-25

巡检四足机器人应用方案与解析

随着工业化和智能化的快速发展,电力、石油化工、隧道等特殊场景的巡检需求日益增长。这些环境往往具有高风险、高复杂性和恶劣条件(如高温、高湿、辐射、毒气等),对传统人工巡检提出了严峻挑战。巡检四足机器人作为一种智能化、稳定性高的自动巡检设备,能···

2024-12-08

无人机森林防火巡检解决方案概述

随着全球气候变化和人类活动的加剧,森林火灾已成为一种日益严峻的自然灾害。传统的森林防火巡检方法常常受到地形复杂、人力资源不足和视野受限等因素的制约,难以实现对广阔森林区域的全天候、全方位监控。无人机技术的迅速发展为森林防火提供了一种创新的解···

2024-08-26

移动蓄水池:森林防火的灵活水源保障与智慧储水革新

随着全球气候变化加剧,森林火灾频发且破坏力增强,传统消防水源供给模式面临严峻挑战。山区地形复杂、水源分布不均,导致火灾初期扑救效率低下。

2025-04-18

智慧应急平台是干什么的

生活中时不时会发生突发情况,而智慧应急平台的出现将极大地提高我们在危急时刻的自救和互救能力。鼎跃安全推出一款全新的智慧应急平台,旨在为公共机构、企业和个人提供高效、智能化的应急管理工具,确保生命安全和财产保障。首先,智慧应急平台实现了全方位···

2024-05-06

智慧应急平台由什么组成

智慧应急平台能处理应急事件发生的复杂情况,实现资源的合理调配,增加事件处理响应速度。同时智慧应急平台在森林防火、台风预警、水域监测、城市执法等领域有着广泛的应用, 但是你知道它是有什么部分组成的吗?智慧应急管理平台是由数据采集和环境检测系统···

2024-05-05

智慧应急方案

随着时代的快速发展,所需处理的碎片化信息急剧增多,当应急事件发生时,这种情况对应急管理工作带来了更大的挑战。碎片化的信息意味着信息来源广泛、种类繁多、数量庞大,这增加了信息筛选、整合和分析的难度。在应急事件中,快速、准确地获取和处理信息对于···

2024-04-24

森林火灾的预防

加强森林防火宣传教育,提高公众对森林防火的认识和重视程度,也是预防森林火灾不可或缺的一环。综上所述,森林火灾预防需要综合施策,从多个方面入手,才能有效减少火灾的发生,保护森林资源和生态环境的安全。

2024-04-12

城市综合执法方案

城市日常巡逻执法和应急协同调度是城管执法行业的工作特点和重点。执法人员依靠日常的巡逻工作发现违章搭盖、占道摆摊等行为,以教育、警告或罚款等形式进行规范管理。当发生突发事件时,指挥中心调度执法人员前往现场规范管理或是协助其他部门执法人员(如工···

2023-09-25

便携式移动消防炮:灾害救援与消防灭火的高效解决方案

在灾害救援和消防灭火领域,便携式移动消防炮作为一种高效、灵活的灭火设备,正逐渐成为应对火灾事故的重要工具。随着火灾事故的复杂性和多样性不断增加,传统消防设备在某些场景下难以快速响应和有效灭火。便携式移动消防炮以其轻便易携、高效灭火、操作灵活···

2025-04-14

汽柴油发电机在实际救灾中的解决方案

汽柴油发电机在救灾中的应用不仅仅是为应急救援提供电力支持,更是保证救援工作高效进行、减少灾后影响的重要工具。通过合理的选型、配置和燃料管理,汽柴油发电机能够有效地为灾区提供持续电力,为灾后恢复提供重要保障。因此,发电机的准备和应用,是每一个···

2025-02-03

应急照明系统:360°移动全景照明系统应用案例

某沿海城市因强台风侵袭,大范围区域出现断电、道路中断等情况,给救援行动带来了极大挑战。特别是在夜间,由于缺乏照明,救援队伍的行动效率受到严重限制,灾区群众的安全得不到保障。在此次救援中,360°移动全景照明系统发挥了重要作用,为夜间救援工作···

2025-01-19

消防避火服:集成机制防护、隔热抗撕,筑牢生命防火墙

消防避火服集成的机制防护、隔热抗撕性能和人体工程学设计,为消防员在火场中的生命安全筑牢了一道坚固的防火墙。

2024-10-29

手持扩音器在应急救援中的实施方案

手持扩音器作为一种高效的声音传递工具,能够在嘈杂环境下确保指令的有效传递。其便携性和灵活性使其成为救援任务中的重要装备。

2024-10-28

移动厕所部署:确保灾区群众如厕需求与卫生防线的综合方案

移动厕所的部署是灾后恢复工作中至关重要的一环,通过科学规划、合理布局、严格管理和有效维护,能够真正为灾区群众提供一个安全、卫生、舒适的如厕环境,更是推动灾区社会秩序和社区生活迅速重建的基础。

2024-10-24

长沙市防山火在线监测装置安装项目

长沙市山区周边山林茂密、植被丰富,夏秋季节高温干燥,火险等级高。线路一旦发生山火,不仅会威胁供电安全,也可能造成大面积森林资源损失。为提升山区线路安全保障能力,运维部门在长沙市山区周边部署防山火在线监测装置,实现火情的实时自动监测和预警,为···

2025-12-02

广州市防山火在线监测装置安装项目

广州市山区地势高、山林茂密、植被丰富,夏秋季节高温干燥,火险等级高。线路一旦发生山火,不仅会威胁供电安全,也可能造成大面积森林资源损失。为提升山区线路安全保障能力,运维单位在广州市山区周围部署 防山火在线监测装置,实现火情的实时自动监测和预···

2025-12-02

南昌市输电线路分布式故障定位设备安装项目

南昌市部分区域线路跨越农田及道路,周边负荷密集且雷雨天气频发。传统故障查找依赖人工巡线,周期长且效率低,遇突发故障时可能导致停电时间延长,影响区域供电可靠性。为提高线路故障查找速度及精准性,运维部门决定在南昌市部分区域部署分布式故障定位设备···

2025-12-02

南宁市双目测距图像视频监测装置安装项目

南宁市作为重要供电通道,其中城区人流密集、活动频繁。该区域对线路安全运行的可视化监控需求尤为突出。同时,杆塔周边环境复杂,需对导线弧垂、异物距离、通道安全距离等关键参数进行精确监测。为提升线路精细化巡维与风险预警能力,运维单位在城区部分区域···

2025-12-02

昆明市山区输电线路防山火在线监测装置安装项目

昆明市山区森林密布、植被丰富,夏秋季节高温干燥,山火风险突出。山林地带一旦发生火情不仅威胁输电线路安全,也会影响区域供电和森林资源安全。为提升山区线路的安全运行能力,运维单位在昆明市山区通过部署防山火在线监测装置,构建早发现、早预警、早处置···

2025-12-02

天津市输电线路在线视频监测装置安装项目

天津市输电线路跨越交通路段,为车辆密集、高速通行区段,线路安全风险较高。传统人工巡线周期长、难以及时掌握线路运行状态,尤其在恶劣天气下巡查困难。为提高线路运行可视化管理水平、及时发现杆塔及导线异常,运维部门决定在 天津市密集交通路段部署视频···

2025-12-01

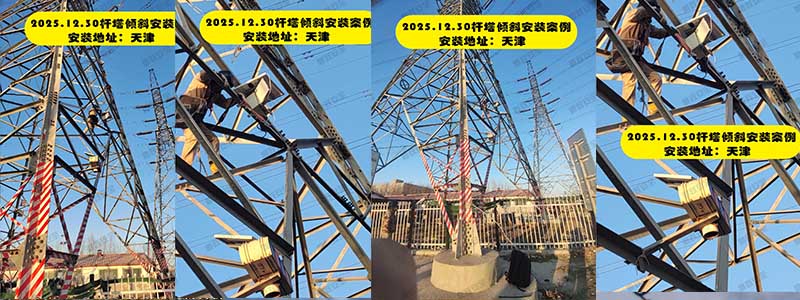

12.30天津杆塔倾斜在线监测装置安装项目

天津地区部分输电线路穿越城市道路、软土地基及施工活动密集区域,受地基沉降、地下工程施工、长期荷载变化等因素影响,个别杆塔存在倾斜风险。为加强杆塔结构安全管控,提升输电线路运行可靠性,运维单位在056号杆塔部署杆塔倾斜在线监测装置,实现对杆塔···

2025-12-30

秦皇岛市防导线舞动在线监测装置安装项目

是秦皇岛地区的核心主网输电线路之一,线路跨越区域广,沿线地势开阔,当地风口明显、风速变化频繁,是导线舞动的典型高风险点。在冬季大风、强冷空气与风切变条件叠加时,导线极易出现周期性振动,造成:

2025-12-04

长春市输电线路防导线舞动在线监测装置安装项目

长春地区的重要输电通道,承担着城市中心及周边乡镇的主网供电任务。地形开阔,冬季盛行偏北风,低温与风速耦合作用明显,是导线舞动的高发区域。

2025-12-04

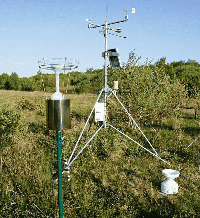

保定市输电线路微气象在线监测装置安装项目

项目名称:输电线路微气象在线监测系统建设安装地点: 保定市安装设备: 微气象在线监测装置(风速、风向、温度、湿度、气压实时采集 + 数据远程传输)完工时间: 2025年7月3日一、项目背景保定市区域属于多风、雨量适中地带。微气象变化直接影响···

2025-12-03

承德市输电线路覆冰在线监测装置安装项目

承德地区冬季气候寒冷、湿度高,线路覆冰现象频发,尤其在地形复杂、海拔起伏大,风雪天气容易导致导线覆冰加重,进而产生断线、跳闸等安全隐患。为保障迎峰度冬期间线路安全稳定运行,运维单位决定在承德较寒冷地区安装覆冰在线监测装置,实现导线覆冰厚度、···

2025-12-03

沈阳市观冰与防舞动在线监测装置联合建设项目

沈阳市国道交通干道,冬季沿海湿冷气候易形成导线覆冰,同时线路受风偏影响较大,存在舞动风险。覆冰和舞动均可能造成导线疲劳损伤、金具受力异常甚至跳闸事故,对线路安全运行带来挑战。为提升线路冰灾及风振预警能力,运维单位在国道部分区域部署观冰在线监···

2025-12-02

银川市高压电缆故障与隐患监测装置安装项目

110kV作为银川市重点供电线路,负责城区及工业园区的稳定供电。01号杆段电缆长期运行,存在局部放电、绝缘老化及过温隐患,传统人工巡检难以及时发现潜在故障,可能影响线路安全稳定运行。为增强线路安全运行能力,运维部门在 01号杆塔安装高压电缆···

2025-12-17

贵阳市高压电缆故障与隐患监测装置安装项目

110kV作为贵阳市重要供电线路,承担城区及周边工业园区供电任务。由于这段电缆长期运行,存在绝缘老化、局部放电及过热等潜在隐患,传统人工巡检难以及时发现问题,存在供电安全风险。为保障关键区域安全供电,运维部门在贵阳110kV安装高压电缆故障···

2025-12-17

柳州市输电线路高压电缆故障与隐患监测装置安装项目

柳州市城区及学校周边,线路供电范围涵盖多个居民区,负荷密集,对线路安全性和稳定性要求极高。由于部分区段采用电缆与架空混合线路形式,电缆在长期运行中可能出现绝缘老化、局部放电、温升异常等隐患,传统人工巡检难以及时发现问题。

2025-12-03

清远市配网故障定位设备安装项目

清远市输电线路覆盖城区及商业区,供电负荷大,居民及商业用电对供电可靠性要求高。传统人工巡检及故障排查耗时较长,一旦线路发生故障,会造成停电范围广、恢复时间长,影响区域供电稳定。为提升配网线路运行安全性和故障处理效率,运维部门在市区部分输电线···

2025-12-03

南京市非接触式故障定位设备安装项目

南京市山区线路跨越丘陵及林地,雷雨及风荷载频繁,线路易受外力及自然因素影响发生短时故障。传统接触式故障定位方式存在停电、施工风险高及响应时间慢等问题,难以满足山区线路高效运维需求。为提升线路运行安全性和故障处理效率,运维部门在南京市山区线路···

2025-12-03

太原市分布式故障定位设备安装项目

太原市线路跨越城区与郊区结合地带,雷雨及风荷载频繁,线路容易因外力影响或天气因素发生短时故障。传统人工巡检响应慢,故障定位周期长,存在停电时间延长的风险。为提升线路运行安全性和故障处理效率,运维部门在太原市线路安装分布式故障定位设备,通过多···

2025-12-03

保障生命安全,防汛应急包为您守护家园

随着气候变化加剧,极端天气频发,暴雨、洪涝灾害成为许多地区面临的现实威胁。防汛应急包正是为此而设计的多功能应急装备,能够在洪灾和台风来袭时为您和家人提供紧急保护。

2024-11-05

水上救生滚钩,紧急救援中的隐形英雄

救援人员借助滚钩,远距离精准锁定并挂住桥梁的残骸,迅速架设救援绳索,并通过滚钩的固定力将绳索稳固在合适的位置上,成功在几分钟内架设了通道,安全转移被困人员。这种快速而精准的救援手段为避免更大伤亡赢得了宝贵的时间。

2024-10-27

浮艇泵,提升排水效率_鼎跃安全

浮艇泵是一种专为水面作业设计的排水设备,由泵体和浮筒组合而成,具备良好的浮力和稳定性。它可以在水面上自由漂浮,适用于各种水域,如湖泊、河流和洪灾现场。

2024-10-22

模块化防洪屏障,抗击洪水的快速响应工具

组合式防洪板由多个模块化板材构成,可快速拼接为防洪墙,坚固结构能抵御洪水冲击,防止水流侵入建筑与关键基础设施。其模块化设计可依需求调整高宽,适应多样地形与水位,能安装在城市河道、地下车库入口等场所,洪灾后易拆卸存储。

2024-10-20

应急救援中的全能助手,移动式排水发电照明泵站

移动式泵站主要配备高效泵站,集排水、发电与照明功能于一体。它能在洪涝、内涝区域迅速排水,适用于城市街道、地下通道、隧道和农田等。在断电时可自带发电功能,为救援设备、医疗设施和通讯系统等提供紧急电力,无论城市还是偏远地区都能维持供电。

2024-10-19

快速排水利器,垂直供排水抢险车

垂直供排水抢险车是一种专门用于灾害救援和应急抢险的多功能车辆,主要用于快速应对洪水、内涝、地下空间积水等水灾情况。它具备强大的供水和排水能力,能够在灾害发生时迅速展开工作。

2024-10-18

成都航空障碍灯安装项目

高压输电线路在穿越机场、河流及低空飞行航道时,存在航空安全隐患。低空飞行器可能受到导线干扰,带来飞行安全风险。为了保障航空安全及输电线路运行安全,运维部门在03号杆塔 安装 航空障碍灯,增强导线可视性,降低低空飞行碰撞风险。

2025-12-25

衢州高压线下防垂钓智能警示杆安装项目

沿线水域及河道常有垂钓活动,部分高压线路杆塔附近存在垂钓触碰线路的风险,容易引发停电、设备损坏或人身安全事故。为了保障线路安全和公共安全,运维部门在11号杆塔周边水域安装高压线下防垂钓智能警示杆,实现智能提醒、实时监控和异常告警。

2025-12-25

郴州电力智能安全警示器安装项目

高压输电线路沿线存在施工、车辆通行及农用机械作业等外部风险,容易发生触碰或接近高压线路的危险情况,影响线路安全与人员安全。为了加强线路安全管理,运维部门在09号杆塔 安装 电力智能安全警示器,实现实时高压线路周边可视化提醒与智能告警,降低外···

2025-12-24

惠州市高压线防外破智能警示球安装项目

随着城市建设及农业作业范围扩大,高压线路周边活动频繁,外力破坏(如吊装作业、车辆碰撞、农用机械接触等)风险增加。外破不仅影响线路安全,还可能导致停电、设备损坏和人身安全事故。为提高线路安全防护能力,运维部门在12号杆塔附近 安装 高压线防外···

2025-12-22

深圳市高压取电防外破警示装置安装项目

高压取电点通常用于设备运维、应急供电和线路检修,但线路周边存在外力破坏风险,例如作业车辆或施工设备可能意外接触取电点,导致停电或安全事故。为保障线路运行安全与作业人员安全,运维部门在08号杆塔取电位置 安装 高压取电防外破警示装置,实现智能···

2025-12-22

贵阳市输电线路航空标志球安装项目

高压输电线路在穿越山区、河流及机场周边时,存在航空安全隐患,飞行器低空飞行易受到导线影响。为了保障航空安全与线路运行安全,运维部门在 220kV安装航空标志球,提高高压线路可视性,减少低空飞行碰撞风险。

2025-12-19

卫星电话,偏远地区与灾难救援的通信生命线

卫星电话是一种基于卫星网络的无线通信设备,利用地球同步轨道或低轨卫星进行语音和数据传输。它通过与地球轨道上的通信卫星直接连接,实现全球范围内的通信,无需依赖地面网络设施,能够保障通信畅通,为救援行动提供了可靠的支持和生命保障。

2025-01-01

灵活适应,高通量卫星便携站满足多元通信需求

高通量卫星便携站应用于救援行动,能够提高紧急行动的响应速度;此装备的使用培训和操作将提升救援团队的通信能力,使救援行动更加高效、精准,从而拯救更多生命。

2024-12-29

窄带自组网基站系统,灵活应对灾害,构建通信生态

窄带自组网基站系统能快速搭建通信网络,确保救援指令即时传达,大幅缩短决策与执行耗时,有力提升救援效率;凭借自主性与灵活性,弥补传统通信短板,增强灾害应对实力,提升救援可靠性。

2024-12-28

北斗赋能,腕表变身精准救援利器

北斗腕表融合了北斗卫星导航定位、信息传递、紧急报警等多项功能,是一款集多种高科技于一体的智能设备。其核心特点包括精准定位、双向信息发送功能、超长待机时间、全天候操作能力,以及抗冲击、防水、防尘的坚固设计。通过宣传北斗腕表的实用性和可靠性,可···

2024-12-27

单兵图传在应急救援中的应用

单兵图传是一种便携式无线视频传输设备,由前端采集设备和无线传输装置组成,能够实时将救援现场的视频、音频信息传输到指挥中心或其他终端设备。该系统支持远程监控、双向语音通讯,甚至与其他救援设备联动,为应急指挥和协调提供强大的技术支持。

2024-12-20

超轻卫星便携站解决通信,轻便与高效的结合

超轻卫星便携站DY-TXE-UPS在台风“摩羯”带来的灾害应对中,凭借其快速部署、稳定通信的特点,极大提升了救援工作的效率与效果。它为灾区的应急指挥和救援行动提供了至关重要的通信保障。

2024-09-09

从防汛到防护,彩条布的全方位作用

近年来,各类突发事件和自然灾害频发,特别是在防汛抗洪、灾后抢险、应急救援等场景中,对现场临时防护和物资快速部署提出了更高要求。彩条布作为一种具有优良防水、防风、耐候性能的应急物资,凭借其鲜明的色彩和简便易用的特点,被广泛应用于灾情现场的应急···

2025-02-09

全方位升降灯:应急救援中的“光明守护者”

全方位升降灯作为一种高效、灵活的照明设备,凭借其高亮度、可升降、全方位覆盖的特点。升降灯还具备防水、防尘、抗冲击等特性,以应对极端环境,确保救援工作高效、安全进行,能够为救援行动提供强有力的支持。

2025-02-04

雪海 “利剑”:破冰除雪车的高效之路

破冰除雪车是一种专门用于清除道路积雪和破除路面冰层的工程机械,广泛应用于城市道路、高速公路、机场跑道及其他重要交通要道的冬季维护。其采用高性能的动力系统,有强大的动力输出,可以应对不同厚度的冰雪清除作用。

2025-01-08

便携式气象仪的应用方案

便携式气象仪是一种轻便、多功能的环境监测设备,能够实时监测并记录气象参数,如温度、湿度、风速、风向、大气压力、降雨量等。

2025-01-05

汽柴油发电机丨电力恢复,心亦安稳

汽柴油发电机利用内燃机原理,通过燃烧汽油或柴油产生动力,驱动发电机产生电力。

2024-09-13

停电克星:应急电源车应用案例

应急电源车作为一种高效的移动发电解决方案,它能够在电力故障发生时,迅速部署至指定地点,为关键基础设施如医院、通讯设施和紧急指挥中心等提供稳定、可靠的电力支持,对减轻灾害影响、保障公共安全及加速灾后恢复具有至关重要的作用。

2024-09-09

筑牢洪涝线:探索领先的防洪解决方案

洪水灾害的威胁始终高悬,以预防为主的核心防洪理念就要求我们具备能够快速部署且可循环利用的防洪措施。另外,因气候变化极端天气频发致使洪涝灾害频发且强度不断增加。我们急需可靠的防洪解决方案,以在洪水来临时迅速部署,最大程度地保护民生安全,同时减···

2024-09-27

燃气泄漏案例

燃气泄漏是一种极为危险的现象,每年都会因此发生多起事故。有些事故因为及时发现并得到了妥善处理,从而避免了更严重的后果。然而,也有一些因为燃气泄漏导致的悲剧性事故,给人们的生命和财产安全带来了巨大损失,甚至造成家破人亡的惨剧。据说有一位居民在···

2024-04-25

抗洪抢险案例

抗洪抢险案例在面对自然灾害时,特别是洪水这样具有破坏性的灾害时,及时有效的抗洪抢险方案至关重要。本方案旨在为各级政府、救援机构和社区提供一套系统的指导,以应对洪水灾害,最大限度地保护人民生命财产安全,减少灾害造成的损失。抗洪抢险方案是应对洪···

2024-04-17

输电线路林区防火智能监控杆:让火情早发现,让输电更安全

输电线路林区防火安全关乎万家灯火与生态存续。传统人防巡检受诸多限制,难以实现火险“早发现、早预警、早处置”,而输电线路林区防火智能监控杆应运而生,以科技之力筑牢双重安全屏障。

2026-02-04

户外安防选什么?太阳能语音监控杆,无需市电更便捷

太阳能语音监控杆以阳光为动力,褪去设备的冰冷感,化作户外安防的守护者,打破传统监控局限,将环保节能与智能防控深度融合,书写户外安防新图景。

2026-02-04

高压细水雾灭火机:环保无残留,防火更高效

火灾动辄吞噬家园与生命,在防火守护中,高压细水雾灭火机以水为刃、以技为盾,打破传统灭火局限,用温和且强劲的力量筑牢安全防线。

2026-02-03

山林/工地应急必备!便携式灭火水泵,快速部署

火能点亮文明,亦能瞬间酿成灾难。当大型消防设备受地形、道路限制无法及时抵达,便携式灭火水泵便化身守护卫士,以小巧身躯、强劲动力,在灭火黄金时间挺身而出,用奔腾水流筑牢安全防线。

2026-02-03

高压接力消防水泵 vs 普通消防水泵,区别一目了然

当烈火肆虐、浓烟蔽日,高压接力消防水泵便是消防逆行者的坚实后盾,以无声坚守传递生命希望。它无需惊天轰鸣,却能跨越阻碍,将生命之水精准送达火场,用接力之力与火魔对抗,守护家园安宁。

2026-02-02

激光赋能+智能值守,输电线路激光防外破在线监测

纵横交错的输电线路,是城市运转、万家灯火的“生命线”,承载着电能输送的重任,维系着工业生产与百姓生活。但施工违规作业、异物侵入等外力破坏,仍是威胁线路安全的“隐形杀手”,易引发线路跳闸、设备损毁,影响正常用电。在此背景下,输电线路激光防外破···

2026-02-02

高压取电防外破警示装置:守护电网安全的生命防线

电网,是城市运转的血脉,是万家灯火的依托,每一寸高压线路的安全,都牵动着社会稳定与民生福祉。然而,随着城市建设提速、户外作业增多,施工机械误碰、异物侵入等高压电网外破事故频发,不仅造成巨额经济损失,更时刻威胁着运维人员与周边群众的生命安全。

2025-12-31

太阳能语音广播杆:防水抗造易安装,户外省心又高效

一根矗立的太阳能语音广播杆,以阳光为动力、以声音为载体,将环保初心与便捷宣传相融,在偏远角落、危险区域、乡村地头,成为守护一方安宁的智能化设备,为科技赋能民生领域提供了简洁高效的解决方案。

2026-02-04

森林消防高压灭火泵:高扬程大流量,山林灭火更高效

当山火裹挟热浪吞噬林海,森林消防高压灭火泵便是最可靠的守护力量。它没有华丽外表,却以强劲动力和坚韧性能,成为消防员的亲密战友,以水为刃划破浓烟,守护着我们珍视的绿色家园与绿水青山。

2026-02-04

轻便易操作,灭火无负担|移动式高压细水雾灭火装置

消防安全是万家灯火的底线,火灾突发时,高效灵活的灭火设备至关重要。移动式高压细水雾灭火装置,以科技为支撑、责任为核心,用细腻水雾筑起防火屏障,默默守护生活的每一处角落。

2026-02-03

破高差、输清泉,高扬程水泵赋能民生与工业

在山河沟壑、高楼楼宇与田间地头,高扬程水泵始终沉默坚守,跨越地势阻隔,将清泉送往所需之处。它不事张扬,却以强劲动力打破高低落差桎梏,承载着灌溉、供水、工业生产的重要使命,用匠心书写温情与担当。

2026-02-03

便携式移动消防炮,快速部署、安全控火两不误

当火光肆虐、浓烟弥漫,便携式移动消防炮便是逆火而行的“守护使者”。它身形轻便,能抵达消防车难以触及的险境,喷射强劲水流抵御火魔,用机动高效,承载着对生命的敬畏与守护。

2026-02-02

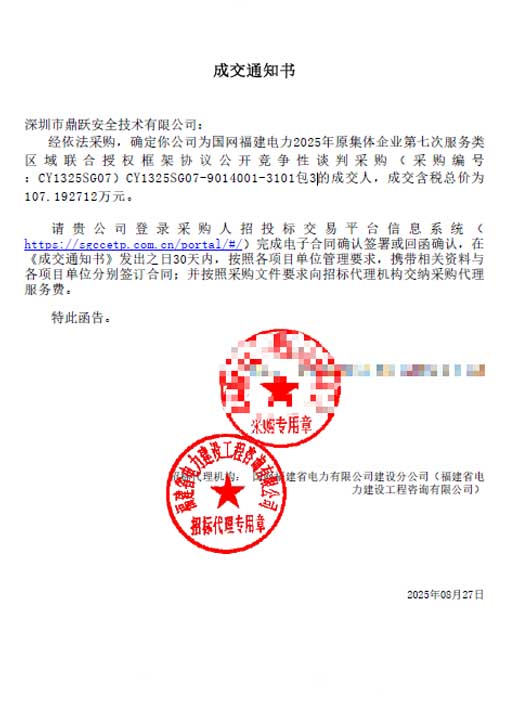

2025年8月27日 我司成功中标国网福建电力2025年联合授权框架协议采购项目!

我们怀着激动的心情宣布:在国网福建电力2025年联合授权框架协议的公开竞争性谈判采购中,深圳市鼎跃安全技术有限公司凭借综合实力、优质服务和卓越的履约能力,成功获得该框架协议的授权!

2025-12-10

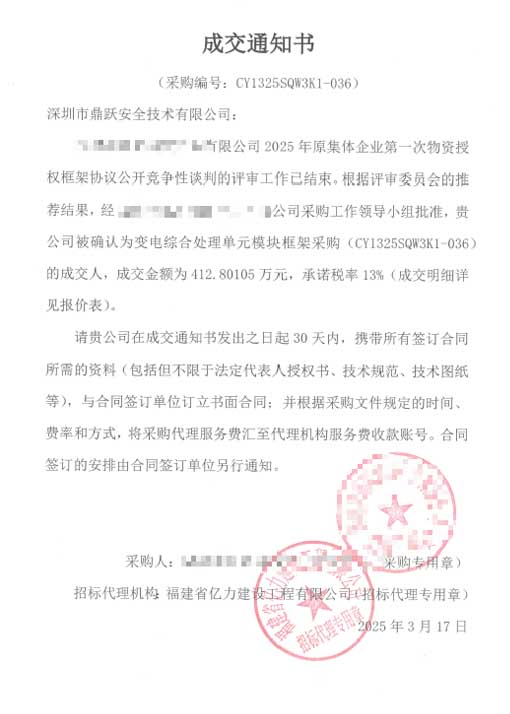

2025年3月17日 我司成功中标变电综合处理单元模块框架采购项目!

我们怀着无比激动的心情宣布:在严格的技术评审和商务谈判中,深圳市鼎跃安全技术有限公司凭借在电力自动化和硬件集成领域的深厚积累,成功中标变电综合处理单元模块框架采购项目!

2025-12-10

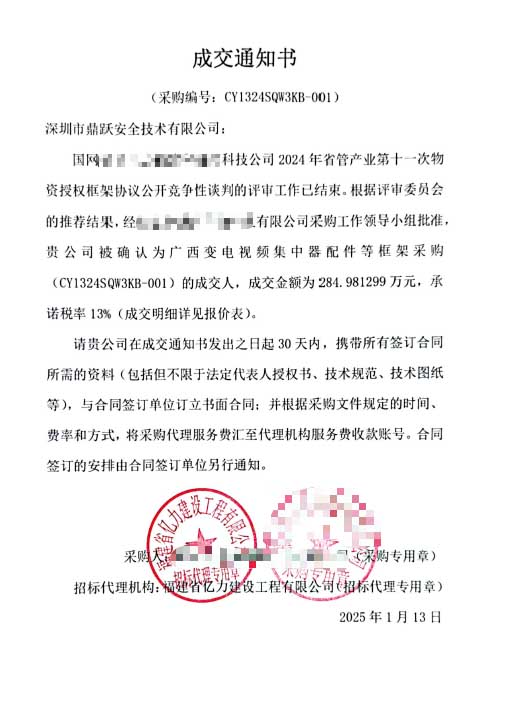

2025年1月13日 我司成功中标广西变电视频集中器配件项目!

我们怀着无比激动的心情宣布:在激烈的市场竞争中,深圳市鼎跃安全技术有限公司凭借卓越的技术实力、可靠的产品质量和完善的服务体系,成功中标广西变电视频集中器配件采购项目!

2025-12-10

As a critical component of high-voltage transmission line systems, the structural safety of transmission towers directly impacts national economic development and public welfare. With the continuous strengthening of China's national capabilities, transmission towers have progressively evolved toward larger-scale designs. However, these vital transmission tower structures typically exhibit characteristics of height and flexibility. making wind loads, tower-line tension, and geological settlement the controlling loads in their structural design. In recent years, incidents of transmission tower collapses and failures under these conditions have occurred domestically, severely jeopardizing grid safety. Therefore, it is imperative to establish a reliable dynamic reliability analysis method for evaluating transmission tower structures under the combined effects of wind loads, tower-line tension, and geological settlement. This approach will provide a solid foundation and support for future transmission tower design and construction.

The BeiDou Radar Deformation Visualization Monitoring Device primarily monitors target displacement through interferometric surveying. Two key technologies within this system ensure high-precision, long-range displacement monitoring: interferometric surveying and linear frequency-modulated continuous wave (LFM-CW).

Interferometry is currently a highly mature measurement technology that primarily ensures precise measurement of displacement changes in target objects. This technology operates by detecting phase differences in radar reflected waves. The initial transmission and reception of radar waves establish the target's position and phase information. Subsequent transmission and reception determine phase information at a second location, with precise displacement changes calculated through phase difference analysis. Theoretically, the minimum detectable displacement change is 0.000000068 mm—a precision level fully meeting the demands of industries such as bridges, buildings, towers, and slopes.

This technology enables the measurement of radial displacement of the target object. The processing software can directly calculate displacement projections in other directions. Users can freely configure the geometric relationships of these projections to perform deformation measurements across the entire area.

1. Collect vibration parameters for each tower foundation and wind vibration intensity parameters for conductors and ground wires, conduct safety assessments, and ensure the safety of transmission towers during operation.

2. Capable of backend algorithm processing and analysis, data storage, data modeling, and intelligent assessment of tower safety status;

3. Equipped with data security encryption capabilities and capable of connecting to the unified power grid platform;

4. Implement digital management of test data, enabling authorized personnel to access on-site tower safety data and safety assessment information via Ethernet or mobile devices based on their respective permissions.

5. The system not only enables remote early warning for problematic towers but also provides emergency response plans upon tower failure. Through the GIS system, it promptly locates the tower's geographic information and dispatches personnel for intervention.

Implement emergency measures such as entry, maintenance, and reinforcement to reduce the likelihood of accidents occurring;

6. Utilizing wireless transmission via 3G/4G networks eliminates the need to install sensors in the target area or approach/enter the target for measurement. With an accuracy of 0.01mm, the device captures even the slightest deformations of the target. It enables both dynamic and static monitoring of the target object, with user-configurable sampling frequencies. High-frequency data acquisition supports sampling rates up to 200Hz.

7. Accurately analyze the vibration characteristics of the target object within the 0–50 Hz range to obtain its multi-frequency vibration spectrum.

8. Modal analysis can be performed on the target object to extract its vibration modes at multiple natural frequencies.

9. Capable of providing continuous data acquisition under all weather conditions, including rain, wind, fog, etc.

10. Direct, real-time monitoring: By analyzing information from individual pixels, the deformation of the entire target can be determined. Continuous 24-hour monitoring of the entire target is possible, with remote measurement capabilities eliminating the need for on-site personnel.

The main unit of the online radar deformation monitoring system for transmission towers is a data acquisition and processing system specifically developed by our company for power line surveillance. It enables remote data collection and processing via 4G/3G/GPRS/CDMA wireless networks. The system supports integration of radar deformation data, micro-meteorological data, tension data, inclination data, vibration data, and stress data, providing rational data assurance for the safe operation of transmission lines.

The spatial resolution of this system includes: - Distance resolution: 50 cm, meaning the distance dimension is divided into units of 0.5 m. - Maximum data sampling frequency: 200 Hz. Users can configure settings according to actual conditions.

The maximum monitoring distance of this system is 1 km, which users can freely adjust according to actual requirements. With a measurement accuracy of 0.01 mm, the device can detect even 0.01 mm deformations in the target object.