Toxic Gas Detector: Tailored Gas Detection Solutions for Fire and Chemical Facilities

In industries such as chemical manufacturing, petroleum refining, and pharmaceuticals, where potential chemical leaks pose significant risks, rapid and precise toxic gas detection is crucial for ensuring employee safety, preventing environmental contamination, and minimizing property damage. According to the "Requirements for Emergency Rescue Material Provisioning in Hazardous Chemical Units," enterprises must equip themselves with appropriate emergency rescue supplies. Among these, toxic and hazardous gas detectors serve as critical emergency rescue equipment, playing an indispensable role in toxic gas detection and prevention.

Toxic and hazardous gas detectors can promptly detect leaks of toxic gases in the air and alert personnel on-site to take emergency measures through an alarm system. Their importance lies in: real-time monitoring and early warning to prevent hazardous situations, protecting employee safety, reducing the impact of toxic gases on employee health, and lowering the incidence of poisoning incidents.

Equipment Configuration and Deployment Principles

According to the "Requirements for Emergency Rescue Material Provisioning in Hazardous Chemical Units," enterprises should adhere to the following principles when deploying toxic and hazardous gas detectors:

1. Comprehensive Coverage: The deployment of detectors must cover all areas where toxic gas leaks may occur.

2. Specificity: Select appropriate detection technologies and equipment models based on the properties of different gases (such as density, diffusion rate, etc.) and the characteristics of the operational environment.

3. Redundancy: Multiple detection devices must be installed in critical areas to ensure that other devices continue to function normally in the event of a single device failure.

4. Accessibility: Equipment should be positioned for easy maintenance and calibration to ensure long-term stable operation.

Detailed Solution Description

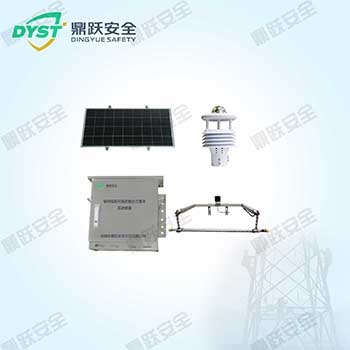

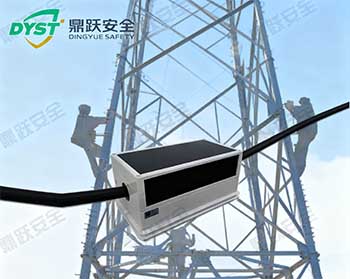

1. Fixed Gas Detection System: Suitable for large-area, fixed-location monitoring such as production workshops and warehouses. Comprising high-sensitivity sensors, audible/visual alarms, and a control center. Capable of connecting to ventilation systems and sprinkler devices to automatically initiate emergency measures.

2. Portable Gas Detector: Designed for safety checks before employees enter confined spaces or perform specialized tasks. Lightweight and easy to carry, it features instant detection and alarm capabilities.

3. Personal Protective Equipment (PPE) Integrated Monitor: Directly integrated into employees' personal protective equipment, such as safety helmets and work uniforms. Provides continuous, real-time monitoring of the individual's surrounding environment.

For entities handling hazardous chemicals, the proper selection and deployment of toxic and hazardous gas detectors not only complies with the "Requirements for Emergency Rescue Material Provisioning in Hazardous Chemical Units" but also demonstrates a commitment to employee safety and the sustainable, stable development of the enterprise. Establishing a comprehensive toxic gas detection network can significantly mitigate risks associated with chemical leaks, ensuring the safe and efficient operation of production activities.

Our company offers the portable toxic and hazardous gas detector DY-SFE-DQY to meet safety monitoring requirements in industrial settings such as chemical, petroleum, pharmaceutical, and metallurgical sectors. Our professional technical team provides customized services including equipment selection, installation and commissioning, personnel training, and after-sales maintenance. This ensures customers can respond swiftly to various emergencies and comprehensively enhance their safety management capabilities.