Application Solutions and Analysis for Quadruped Inspection Robots

I. Background and Requirements Analysis

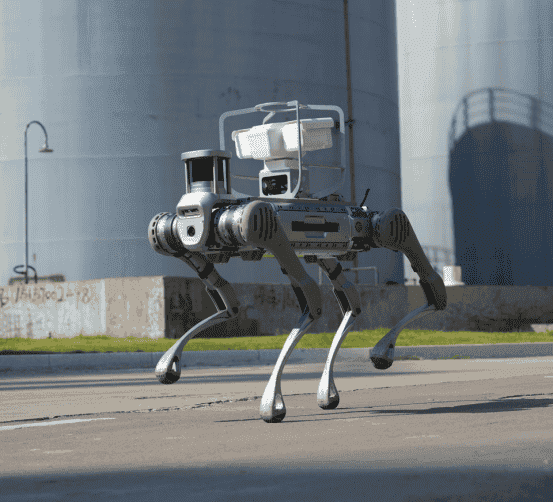

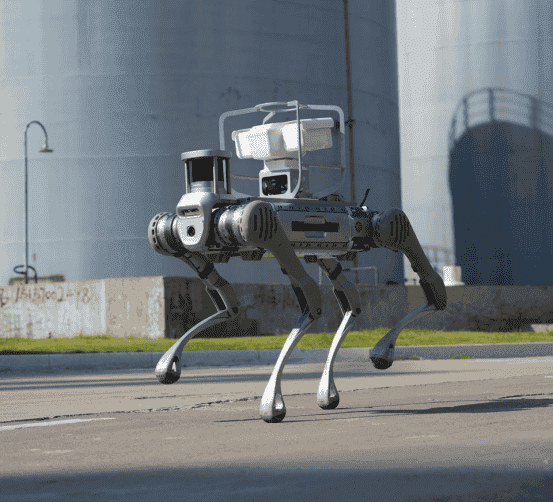

With the rapid advancement of industrialization and intelligent technologies, the demand for inspection in specialized environments such as power plants, petrochemical facilities, and tunnels is growing steadily. These settings often present high risks, complex challenges, and harsh conditions—including extreme temperatures, high humidity, radiation, and toxic gases—posing significant obstacles to traditional manual inspections. As intelligent, highly stable automated inspection devices, quadrupedal inspection robots can replace human workers in diverse complex scenarios, delivering efficient and safe solutions.

II. Application Solution Design

1. Design Objectives

The quadrupedal inspection robot is designed to perform unmanned, intelligent, and round-the-clock inspection operations, ensuring real-time monitoring of equipment status, enhancing inspection efficiency, and reducing personnel risks.

2. Key Functional Modules

Mobility and Obstacle-Crossing Capability

Quadrupedal Bionic Structure:Simulates animal quadrupedal gait with exceptional terrain adaptability.

Autonomous Navigation and Positioning:UtilizingLidar and SLAM technology, it can autonomously plan routes and avoid obstacles.

Inspection and Sensing Functions

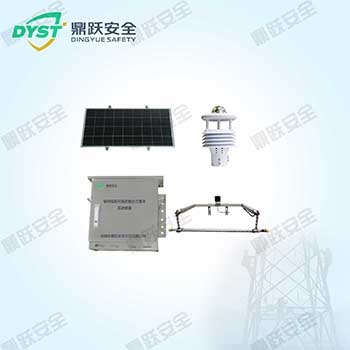

Multimodal Sensor Integration:Equipped with infrared thermal imaging, high-definition cameras, LiDAR, and gas sensors for real-time environmental data collection.

Intelligent Recognition and Analysis:UtilizingAI algorithms to detect anomalies on equipment surfaces, temperature irregularities, gas leaks, and other issues.

Communications and Data Transmission

5G/Wi-Fi Module:Enables real-time transmission of inspection data and remote operation.

Edge computing capabilities: Process critical data locally to reduce communication latency and enhance decision-making efficiency.

Range and Energy Management

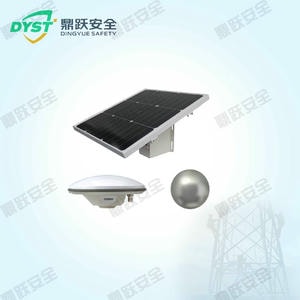

High-efficiency battery pack: Supports extended operation and further extends runtime when combined with solar charging modules.

Autonomous Return to Charging Station:After completing inspection rounds, it can automatically return to the charging station, reducing manual intervention.

Environmental adaptability

Protection RatingIP67:Waterproof and dustproof, suitable for harsh environments such as rainy days and wetlands.

Temperature Adaptation Range: -20°C to 50°C, capable of normal operation under extreme climatic conditions.

3. Typical Application Scenarios

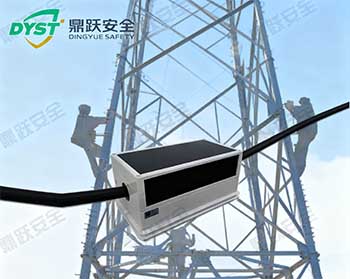

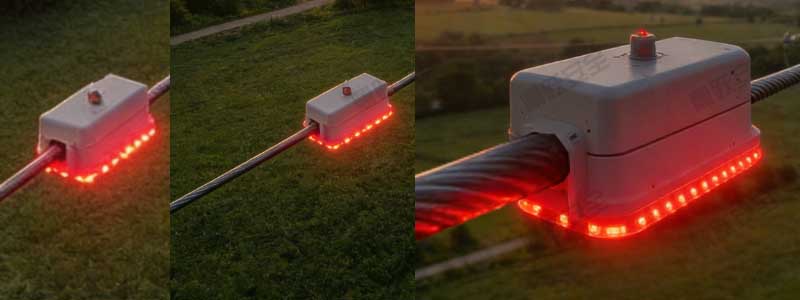

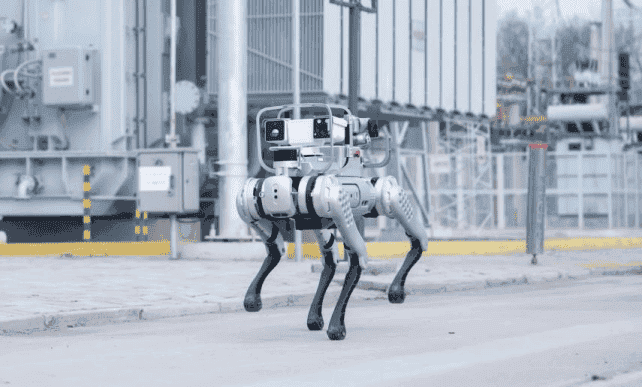

Power Inspection:Applied in scenarios such as substations and transmission lines to detect equipment surface temperatures, line contact conditions, and abnormal noises.

Petrochemical Inspection:Inspecting pipelines and valves for leaks, as well as monitoring toxic gas concentrations in refineries and chemical plants.

Tunneling and Mining Operations:Real-time monitoring of equipment operation, rock fractures, and gas composition within tunnels.

Emergency Detection:Rapidly enter hazardous areas following earthquakes or fires to collect environmental data, providing critical information for rescue operations.

III. Solution Analysis

1. Technical Advantages

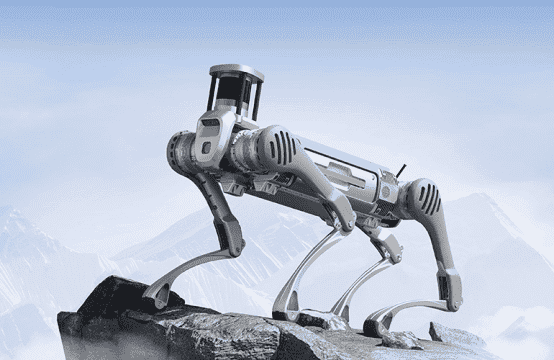

High Mobility:The quadrupedal design grants the robot exceptional stability and obstacle-crossing capabilities, enabling it to navigate complex terrains such as steps, steep slopes, and gravel with ease.

Intelligent Capabilities:IntegratingAI technology to enable autonomous identification and alerting of abnormal events, significantly reducing manual analysis costs.

All-weather operation:Equipped with multiple sensors, it possesses day-and-night inspection capabilities, performing exceptionally well in low-visibility scenarios.

2. Cost-Benefit Analysis

Short-term benefits:Reduce manual inspection frequency, minimize personnel risks, and enhance operational efficiency.

Long-term benefits:Optimize equipment maintenance cycles through data accumulation, reducing failure rates and operational costs.

3. Implementation Challenges and Countermeasures

1. Navigating complex environments is highly challenging.

Countermeasures:Implement high-precision maps and real-time obstacle avoidance algorithms to enhance navigation accuracy and reliability.

2. Data transmission stability is limited.

Countermeasures:Integrate5G communication technology with edge computing architecture to ensure rapid and stable data transmission.

3. Initial investment is relatively high.

Countermeasures:Reduce equipment upgrade and maintenance costs through modular design, extending the product lifecycle.

IV. Practical Case Applications

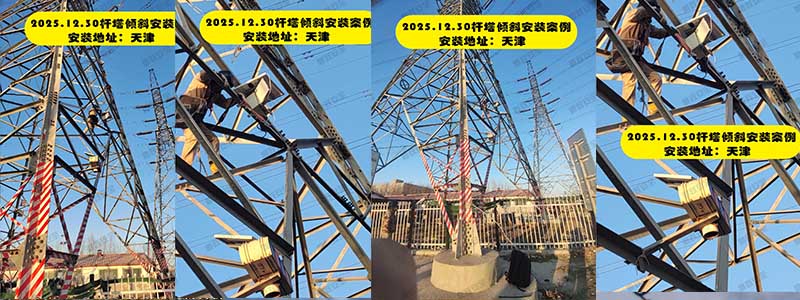

1. Substation Inspection Project for a Power Grid Company

Deploying quadruped robots to conduct multiple full-site inspections daily, successfully identifying 5 high-temperature joints and 3 surface cracks on equipment, significantly enhancing operational reliability.

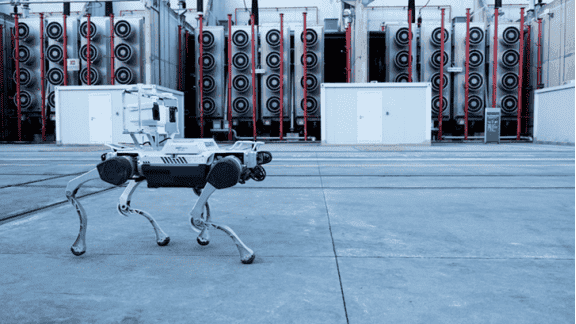

2. Gas Leak Monitoring System for a Chemical Industrial Park

Deploying robots throughout the facility enables continuous monitoring of gas leak concentrations, allowing for the detection and localization of leak points, thereby preventing major safety incidents.

V. Conclusion

The DY-DZE-SZR quadruped inspection roboteffectively addresses inspection needs in specialized environments through intelligent, automated design, offering significant technical advantages and economic value. As technology advances further, its applications will expand considerably, providing robust support for industrial intelligent upgrades.