Handheld Rebar Cutter Application Solutions and Solution Analysis

I. Background and Requirements Analysis

In scenarios such as construction, emergency rescue, and equipment dismantling, cutting rebar is a common yet critical task. Traditional cutting tools often require significant manual labor, are cumbersome to operate, and are inefficient, failing to meet the demands for efficiency and precision in modern engineering. The handheld rebar cutter, as a portable, efficient, and safe cutting tool designed for complex scenarios, significantly enhances rebar cutting efficiency, reduces labor intensity, and provides reliable support for rescue operations in emergencies.

II. Application Solution Design

1. Design Objectives

The rebar cutting tool is lightweight and highly efficient, capable of handling cutting tasks for various rebar specifications across multiple scenarios. Designed with operational safety in mind, it effectively reduces labor intensity for workers while boosting work efficiency. Additionally, it adapts to harsh environments and fully meets the demands of long-term use, making it an exceptionally practical rebar cutting tool.

2. Functional Modules

Power System:This equipment features both electric and hydraulic drive modes. The electric drive utilizes a high-efficiency motor to ensure stable and powerful cutting force; the hydraulic drive delivers greater cutting force, making it suitable for cutting thicker steel bars or materials with exceptional hardness.

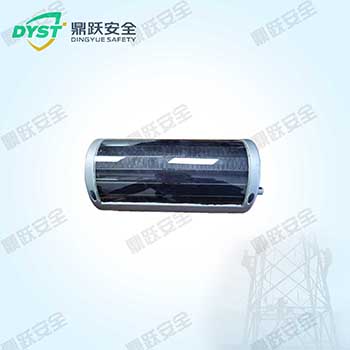

Cutting Capability:It can cut rebar up to 21mm in diameter and features high-efficiency rapid cutting, with a single cut taking no more than 3 seconds, significantly boosting work efficiency.

Safety Design:This device incorporates practical safety features, including an automatic reset function and a two-hand operation protection mechanism.

Portability: This device weighs under 8kg and features a built-in rechargeable battery, enabling wireless operation that eliminates cable constraints. This significantly enhances flexibility and convenience during use.

Durability and Maintenance: Manufactured from high-strength alloy steel, the equipment features a modular design for quick replacement.

III. Application Scenarios

In the construction industry, during on-site rebar processing and installation, it can swiftly cut excess rebar or precisely adjust dimensions. During formwork dismantling, it effectively severs rebar support members, significantly boosting construction efficiency. For emergency rescue operations, at disaster sites like earthquakes or fires, it rapidly clears rebar obstacles to establish rescue pathways. In confined space operations, its portability substantially enhances rescue efficiency. For equipment dismantling and modification, it is suitable for removing and modifying steel structures in industrial equipment, such as complex projects involving bridge maintenance and tunnel construction. In logistics and scrap recycling operations, it enables rapid cutting of scrap steel at recycling yards, facilitating subsequent sorting and transportation.

IV. Solution Analysis

1. Technical Advantages

This device features a brief single-cut cycle time and outstanding continuous operation capability, significantly boosting work efficiency. Compared to traditional tools, its lightweight and compact design allows a single operator to easily complete cutting tasks. With features like automatic retraction and dual-hand protection, it effectively reduces risks associated with cutting operations. Capable of cutting rebar of varying materials and diameters, it adapts to diverse complex work environments, demonstrating exceptional practicality and adaptability.

2. Cost-Benefit Analysis

Short-term benefits:Reduce labor costs associated with manual cutting, enhancing construction and rescue efficiency.

Long-term benefits:Reduce equipment maintenance costs, extend service life, and save overall project costs.

3. Implementation Challenges and Countermeasures

To address insufficient adaptability in harsh environments, a sealed design and corrosion-resistant materials are employed to enhance equipment performance in high-humidity, high-temperature, and other demanding conditions. Considering operational endurance limitations, battery capacity optimization and a replaceable battery solution ensure uninterrupted extended operation. To resolve blade lifespan issues, material hardness and wear resistance are upgraded, while a rapid replacement mechanism is implemented to minimize downtime, thereby improving overall operational efficiency and equipment stability.

V. Analysis of Actual Cases

During rebar operations at a construction site, numerous 22mm steel bars required cutting. After deploying handheld rebar cutters, cutting efficiency surged by approximately 60%, reducing daily manual labor by 2 hours. During earthquake disaster relief operations, rescue teams swiftly cleared rebar obstructions from building rubble using the cutter, gaining precious time to successfully rescue multiple trapped individuals. In industrial equipment demolition and renovation, during tunnel maintenance, the cutter excellently completed the task of cutting steel reinforcement support components, reducing operation time by approximately 30% and effectively lowering construction risks.

VI. Conclusion

The DY-DZE-SDQ Handheld Steel Bar Quick Cutteroffers an efficient, portable, and safe solution for steel bar cutting across diverse scenarios. Its broad applicability and significant technical advantages make it an essential tool in modern construction projects and emergency rescue operations.